17

2021

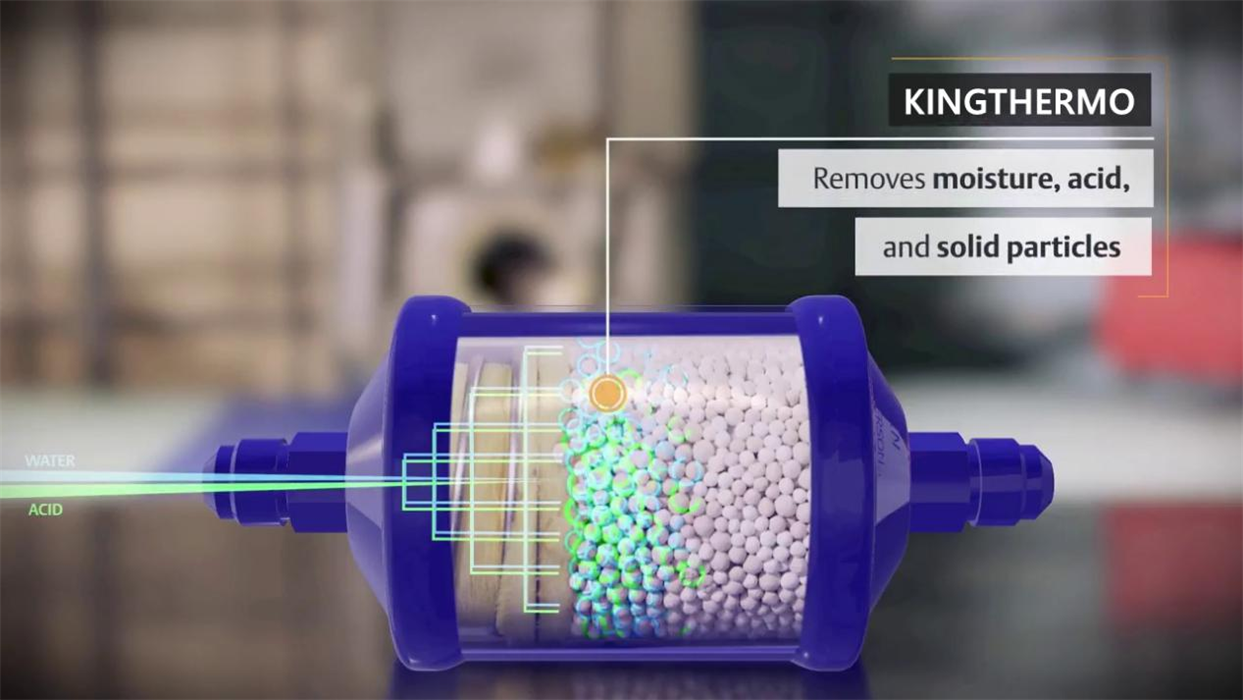

In the refrigeration unit, if water enters into the refrigerant circulation system, the water will react with the refrigerant, resulting in corrosion of pipelines and metal parts, and deterioration of lubricating oil; for Freon refrigeration system, it is also easy to cause “ice jam” phenomenon of the throttle valve.

On the one hand, it is brought into the refrigeration system during the assembly, decomposition and maintenance of the device; on the other hand, it is brought into the system due to the poor quality of the refrigerant and lubricating oil, or when the refrigerant and lubricating oil are filled. In order to remove the water and dirt in the system, the drying filter is usually installed in the refrigeration device.

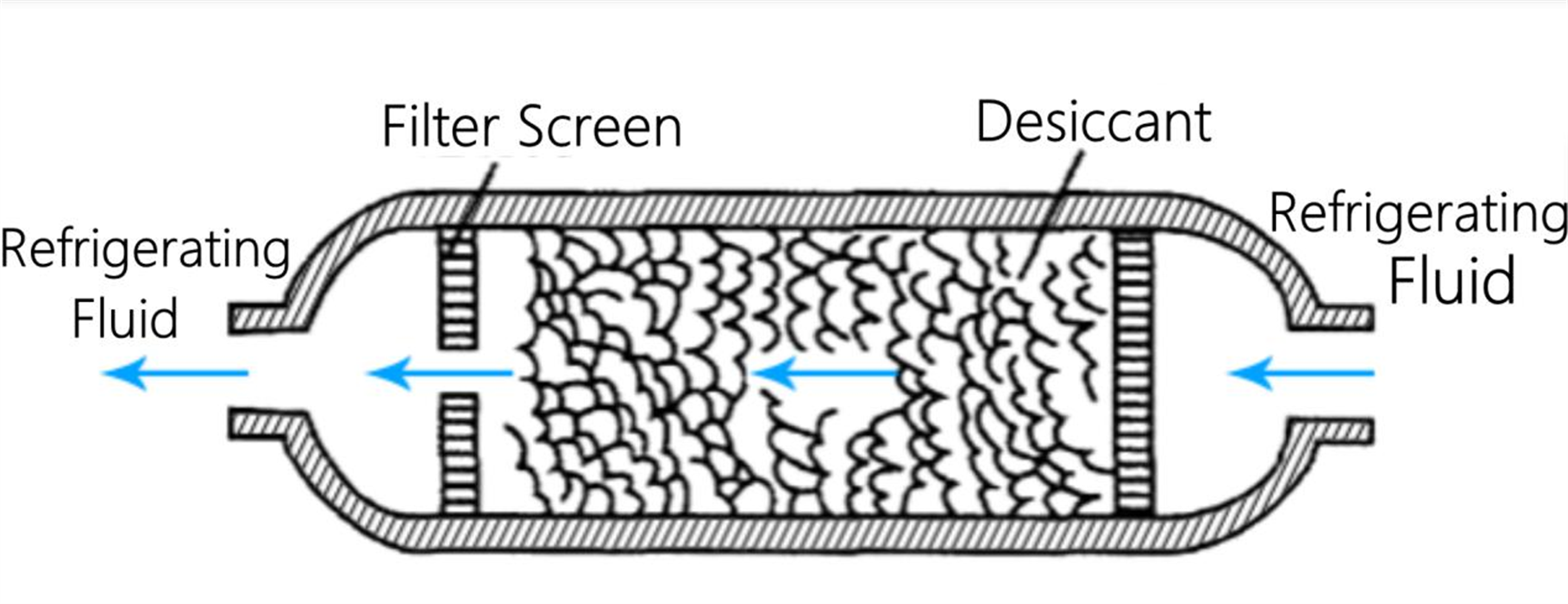

The drying filter is equipped with desiccant and filter screen at both ends, which is directly connected to the pipeline of refrigeration cycle. It can be installed horizontally or vertically. When installed vertically, the refrigerant should flow from top to bottom. For the convenience of disassembly and replacement, some large refrigeration devices only have filter screen at the outlet.

After the drying filter has been used for a period of time, its shell may be cold, condensed or frosted, indicating that the desiccant in it has been saturated with water, and the refrigerant will be partially throttled when it flows through. At this time, the desiccant should be replaced. In addition, if the desiccant in the filter fails, the color of the sight glass will also change. When the filter is replaced, in order to prevent refrigerant leakage or air moisture from entering the system, the re installed part shall be checked after replacement.

Desiccants commonly used in refrigeration system include anhydrous calcium chloride, silica gel, activated alumina, molecular sieve, etc.

Anhydrous calcium chloride (commonly known as quicklime) is a chemical desiccant with strong hygroscopicity. However, it becomes powder or even paste after hygroscopicity, which is easy to enter the system or block the filter screen. Now it is rarely used.

Silica gel is a kind of physical desiccant. Its moisture absorption rate is about 30%. It is a kind of nontoxic, odorless and corrosion-free translucent crystal block. It has coarse pores, fine pores, primary color and discoloration. The macroporous silica gel is quick to absorb moisture, easy to saturate, and short to use; the microporous silica gel is slow to absorb moisture, and long to use; the primary color of the discolored silica gel is sea blue, which gradually turns into light blue and purplish red after absorbing moisture, and finally becomes red and loses its hygroscopic ability. The silica gel can be regenerated by heating at 100-200 ℃ after moisture absorption and saturation, and can continue to be used after sieving the broken particles.

Activated alumina and molecular sieve are white or light yellow porous crystals. The moisture absorption rate of activated alumina is 17%; molecular sieve is a kind of synthetic crystalline aluminosilicate compound, and its moisture absorption rate can reach about 23%. Both of them can be regenerated by heating at 300 ℃ after moisture absorption.

In the liquid supply pipeline of refrigeration device, the reasonable installation of drying filter can reduce the resistance loss of the pipeline and avoid the “flash gas” of refrigerant resulting in the decrease of refrigeration capacity.